Nothing is more important than integrating precision, speed, and persistence during production, and it is vital to achieving high-performance results. Considering the necessity of these factors, lubrication and cooling in industrial machining have emerged to boost machines’ efficiency, sustainability, and lifespan, thereby protecting tool integrity and enhancing product quality.

Lubrication and cooling systems are essential for having reliable and successful modern machine operations. It’s not a simple luxury to adopt or not; it’s a solution that helps leading companies seeking a bright future.

In this article, we will examine the role and impact of lubrication and cooling in industrial machining within modern companies and manufacturers to understand the crucial benefits and merits they can bring to the operation.

Understanding the Importance of Lubrication and Cooling

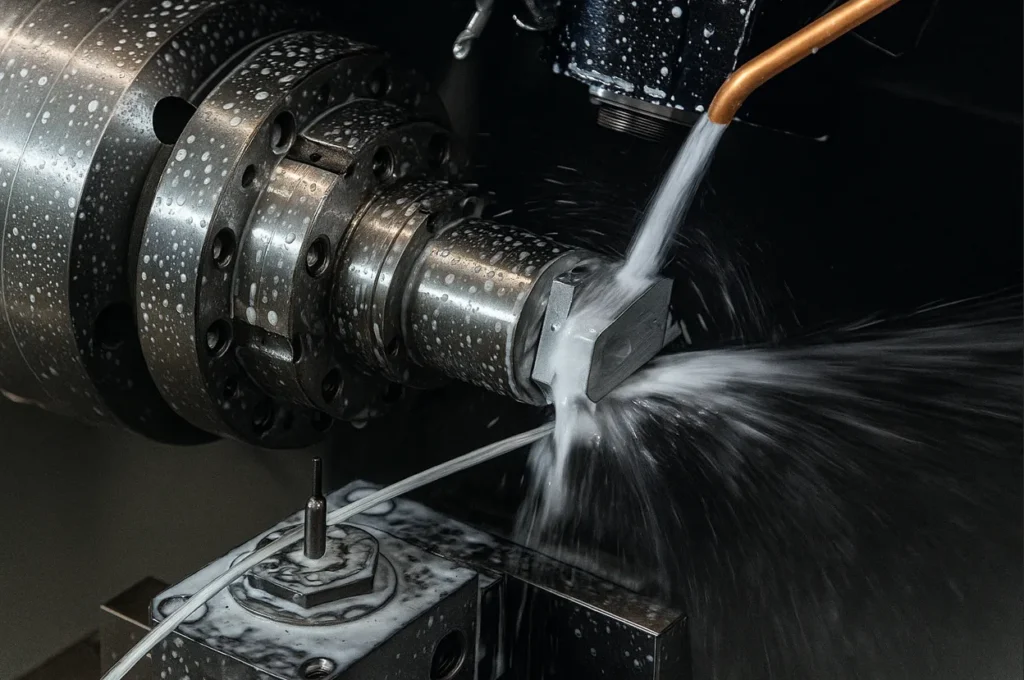

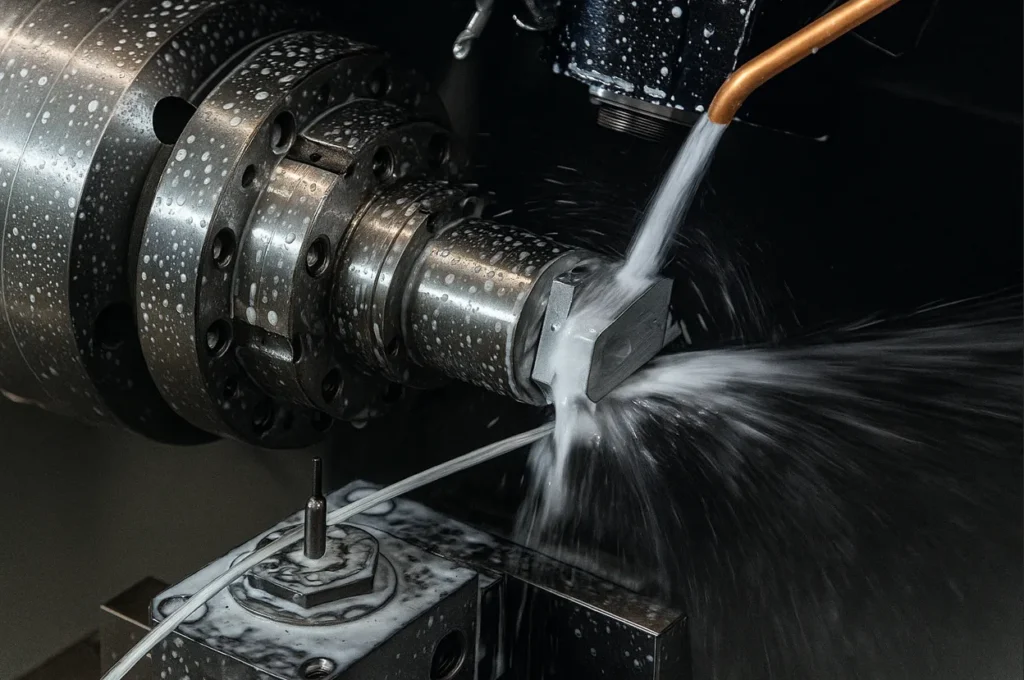

Let’s start with the primary question. What is lubrication and cooling? In short terms, via innovative processes such as drilling, turning, grinding, or milling, materials can be removed from the workpiece through precise and controlled operations.

High-speed operations, especially those involving the removal of hard materials, generate considerable heat and friction between the tool and the workpiece. The primary problem caused by heat is the damage to the lifespan of tools and machines.

It’s a well-known fact that the constant friction leads to rapid tool wear, dimensional inaccuracies, surface burns, and even machine failure if left untreated. This means costly and time-consuming production.

This is where lubrication and cooling are required to reduce the friction between the tool and the material, while simultaneously controlling the excessive heat generated by the cutting process.

Types of Lubricants and Coolants in Machining

Based on the operation needs, a variety of fluids are used, including: These include:

- Cutting Oils: These are mineral-based or synthetic oils used for lubricating and cooling the cutting interface, especially designed to be effective in low-speed, high-load conditions such as tapping or broaching.

- Water-Based Emulsions: Exceptional cooling capabilities are offered by mixing oil and water, typically implemented in high-speed machining. Its capacity to scatter heat quickly while still providing acceptable lubrication is the most significant advantage of this type of lubrication.

- Synthetic Fluids: These are pure chemical compounds, primarily known for providing consistent performance and lower residue accumulation. This is the perfect choice, offering precise and clean lubrication and cooling operation.

- Solid and Air-Based Lubrication: This is an environmentally friendly approach, perfect for special scenarios, such as dry machining. These solid lubricants and compressed air are renowned for producing less contaminated fluid and achieving significant waste reduction.

Functions of Lubrication in Machining Processes

The primary function of lubrication in machining is to form a barrier between the cutting tool and the material surface, minimizing direct contact and thereby reducing wear. This directly prolongs tool life, allowing for more aggressive cutting parameters, which in turn improve cycle time.

Moreover, lubrication plays a role in:

- Chip evacuation: Controlling the re-cutting of chips that could otherwise damage the surface finish or the cutting edge.

- Surface finish enhancement: Lower friction levels ensure smoother surfaces, reducing the need for secondary finishing operations.

- Corrosion prevention: Many lubricants contain additives that protect both the machine and workpiece from oxidation.

The Cooling Effect: A Crucial Thermal Control Mechanism

Another essential feature of the cooling mechanism is maintaining thermal stability during the machining process. This is primarily due to damage caused by excessive heat, which not only distorts the workpiece but also alters its metallurgical properties, leading to complex and compromised mechanical performance.

Coolants absorb and transport heat away from the cutting zone, enabling them:

- Dimensional precision: Thermal expansion is typically reduced in both tools and workpieces by stable temperatures.

- Extended tool life: Lower temperatures reduce the likelihood of thermal cracking or edge softening.

- Higher Safety in Production: The overall safety of the workplace is elevated by reducing temperatures and controlling vapors.

Delivery Methods and System Integration

How the fluids are delivered is equally crucial for adequate lubrication and cooling. This is the main reason why modern machining is equipped with sophisticated fluid delivery systems, including:

- Flood Cooling: By pouring a high volume of coolant over the cutting area, it develops acceptable cooling in general-purpose machining. Flood cooling should be carefully managed and controlled to avoid a wasteful process.

- Minimum Quantity Lubrication (MQL): An environmentally friendly lubrication method where a fine mist of lubricant is sprayed at the contact point.

- Through-Tool Cooling: This method offers precise targeting and effective reach, making it particularly advantageous for deep-hole drilling operations. It is delivered internally via the spindle and cutting tool.

- Cryogenic Cooling: This cutting-edge technique employs exceptionally cold substances, such as liquid nitrogen or carbon dioxide, to hold low temperatures during machining.

Conclusion

The beneficial role of lubrication and cooling in industrial machining processes extends beyond temperature control and tool protection, encompassing a range of additional benefits. These cooling systems are crucial for ensuring production safety, maintaining stability, preserving surface integrity, and enhancing overall operational efficiency.

Implementing an effective cooling system is more crucial than ever in increasingly complex and precision-driven production processes. It’s a vital part of future operations and reliable production in various industries.

Leave A Comment