The comparison of thermal and mechanical metal cutting techniques in industrial applications reveals distinct differences in their impact on material properties, process efficiency, and application suitability. Thermal cutting methods, such as laser and plasma cutting, utilize heat to sever materials, while mechanical cutting involves physical force through tools like saws and shears. Each method has unique advantages and limitations, influencing their selection based on specific industrial needs. The following sections delve into the key aspects of these cutting techniques, highlighting their effects on material properties, process dynamics, and industrial applications.

Material Properties and Hardness

1.Thermal Cutting:

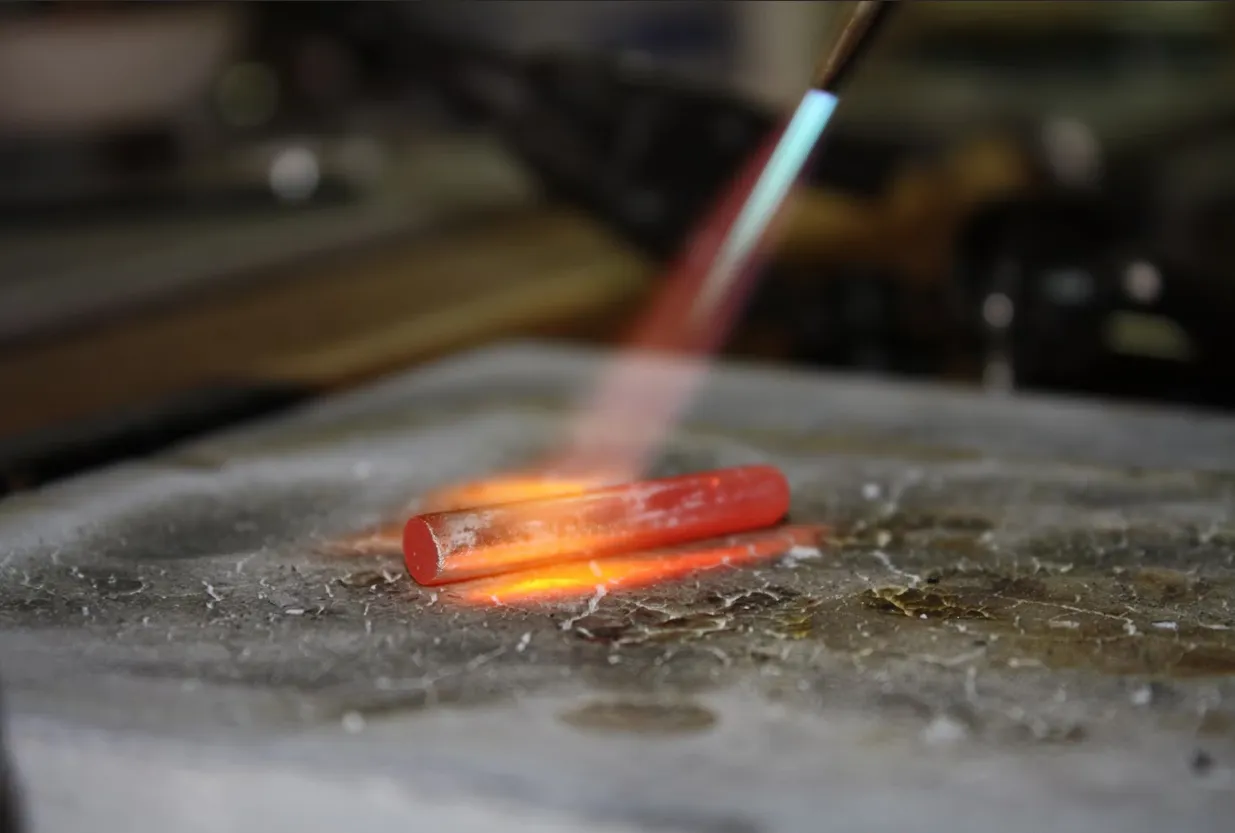

Thermal methods, such as laser and plasma cutting, significantly affect the heat-affected zone (HAZ) of the material. This can alter the hardness and microstructure of the cut edge. For instance, laser and plasma cutting of structural steels S355 and S1100 result in maximum hardness values of 450 HV1 and 550 HV1, respectively, due to the thermal influence on the material. The high temperatures generated during these processes can also cause grain growth or phase changes in certain materials, potentially weakening the mechanical properties of the cut edges. Additionally, the presence of residual stresses, which are induced by the rapid cooling of the heated zone, can further affect the material’s mechanical performance, particularly in high-strength alloys.

2.Mechanical Cutting:

Mechanical cutting processes generally maintain the original material properties more effectively, as they do not introduce significant thermal effects. This results in a more uniform hardness distribution across the cut edge, preserving the material’s integrity. Mechanical cutting methods, such as sawing or shearing, typically induce less stress and heat in the material, ensuring that the microstructure remains relatively unchanged. However, mechanical cutting can lead to surface work hardening, which may slightly alter the material properties near the cut edge. In certain cases, this work hardening may require additional processing, such as deburring or polishing, to restore the desired surface characteristics.

Process Dynamics and Efficiency

1.Thermal Cutting:

These methods are highly efficient for cutting complex shapes and thick materials. They offer high precision and speed, making them suitable for applications requiring intricate designs. However, the thermal nature of the process can lead to residual stresses and potential warping of the material. As a result, post-processing operations such as stress-relieving or further machining may be necessary to mitigate these effects. The speed of thermal cutting is a significant advantage in high-volume production settings, but the potential for material distortion must be considered, particularly in high-precision industries such as aerospace and automotive.

2.Mechanical Cutting:

Mechanical methods are typically slower and less precise for complex shapes but excel in applications where maintaining material properties is crucial. They are less likely to cause thermal distortion, making them ideal for applications where dimensional accuracy and material integrity are paramount. Moreover, mechanical cutting processes are well-suited for materials that require minimal alteration to their microstructure, such as those used in medical or structural applications. While they may be less efficient for large-scale operations, the stability they offer in terms of maintaining material characteristics ensures reliability in the final product.

Industrial Applications

1.Thermal Cutting:

Thermal cutting is widely used in industries such as aerospace and automotive, where precision and speed are critical. The ability to cut through thick materials quickly makes thermal cutting ideal for large-scale manufacturing and complex component fabrication. It is also extensively used for cutting materials like steel and aluminum alloys that benefit from high-speed cutting without compromising basic material properties. In addition to aerospace and automotive, thermal cutting is also valuable in shipbuilding and construction, where large-scale material cutting is essential.

2.Mechanical Cutting:

Mechanical cutting is preferred in industries where the preservation of material properties is essential, such as in the production of components that require subsequent machining or welding. Mechanical cutting is also favored for materials that are sensitive to heat, ensuring minimal alteration to the material’s microstructure. This technique is particularly beneficial in the fabrication of parts that will undergo further processes like heat treatment or surface finishing, where material integrity is paramount. Applications in the medical, tooling, and precision manufacturing sectors often demand mechanical cutting due to its ability to avoid compromising material strength and precision.

Thermal-Mechanical Coupling

The integration of thermal and mechanical effects in cutting processes can provide a comprehensive understanding of the material behavior during cutting. This approach helps in optimizing cutting parameters to minimize adverse effects such as residual stresses and tool wear. By considering both the thermal and mechanical factors, manufacturers can tailor cutting processes to enhance performance and improve the longevity of tools. This integrated analysis can also be beneficial in industries where both speed and material integrity are critical, allowing for better control over the overall quality of the cut.

Conclusion

While thermal cutting techniques offer advantages in speed and precision, they can alter material properties due to the heat involved. Mechanical cutting, on the other hand, preserves material integrity but may lack the efficiency and precision of thermal methods. The choice between these techniques depends on the specific requirements of the application, such as the need for precision, speed, or material preservation. Understanding the interplay between thermal and mechanical effects can further enhance the effectiveness of cutting processes in industrial applications. Through careful optimization and an integrated approach, manufacturers can achieve the ideal balance of efficiency, precision, and material preservation, ultimately improving the quality and performance of their products.

Leave A Comment